PLC DCS SCADA & HMI for Beginners

Let's see how simple we can make it - by first building a SCADA system -

and then by building a DCS system - each from the ground up.

Suppose

that we're building a brand new factory - and suppose that our first

piece of equipment is something like a big industrial oven. This thing

will be made up of heaters, and valves, and conveyor motors, and other

assorted machinery - so let's say we get to work and we build us an

oven. Now that we've got the mechanical part of the oven built - we need

some type of controller for it - something to accurately control all of

those different parts in order to turn raw material into a sellable

final product. So what type of control are we going to use? How about a

PLC - a Programmable Logic Controller?

In very simple language a

PLC is a type of computer. But the computers that most people are

familiar with use a keyboard as an input device and a screen for an

output device. PLC's don't have a keyboard. So for an input device, we

use an "input module" which is basically a little box with a row of

screws on the front of it. We wire up a bunch of pushbuttons, sensors,

switches, etc. to the little screws ... and this will serve as the input

device for our PLC "computer". We do something similar for an output

device. Instead of using a screen for an output device, we use an

"output module" which is basically another little box with a row of

screws on the front of it. We wire up a bunch of solenoid valves,

indicator lamps, motor starters, etc. to the little screws ... and this

will serve as the output device for our PLC "computer".

So for

this first example, let's say that we decide to go with a PLC system. We

buy the PLC and install it by connecting wires between the oven and the

PLC. Then we buy a copy of the programming software from the PLC

manufacturer - and then we write a program for the PLC - we'll probably

use "ladder logic" programming, since that's what most PLC's use as

their native language. And now the PLC is just about ready to properly

control the system - except that we still need some way for the operator

to set and to monitor the temperatures - and to start and stop the

conveyors and so forth.

Now for this small system, some meters

and pushbuttons and some thumbwheel switches might do just fine. We

could wire those up and build us an operator's control panel for our

oven. But another (better?) way would be to use an HMI - a Human Machine

Interface. (This used to be called an MMI - Man Machine Interface - but

now-a-days we've got to be more politically correct.) So we buy us a

nice desktop computer and some type of HMI software. We'll need to

program the HMI - and usually this is done by dragging and dropping

pictures of meters and knobs and buttons onto our computer screen. In

other words, we build a "virtual" control panel for our operator to use.

We link these on-screen controls to the PLC's memory through a

communication cable. And now we're finally ready to go. Great so far -

and we start making some money with our factory.

Later on,

business is good and we decide that our factory could use two additional

ovens. So we get the mechanical parts built - and now we need to decide

how we're going to control these new ovens. Now the original PLC that

we used for oven number one is quite capable of controlling the two

additional ovens. We just might need to add a few additional I/O modules

to the chassis - and we'll certainly need to run some more wires - but

basically the same old PLC "brain" has plenty of extra horsepower to

handle the new ovens. But - here's an idea: Suppose that we buy two new

PLC's - one for each new oven. Now that's certainly going to cost us

more money, but at least this way each oven could operate - or be shut

down - completely separately from the other two systems. That's going to

make scheduling maintenance a lot simpler - and generally give us a lot

more flexibility in all of our operations. Plus - by having three

controllers - we're not putting "all of our eggs in one basket" as the

old saying goes.

We talk the boss into it - and we buy the new

PLC's and install them - and download copies of the original program

into them - and we're just about ready to go. But how about that

operator control piece of the puzzle? Since we're already using an HMI

for our operator's control panel, all we have to do is make two copies

of the screens from our original oven - and set these new copies up on

the operator's HMI computer. Finally, we extend the communication cable

from the HMI station over to the two new PLC's - and now we're up and

running.

Next the boss hires a bean-counter - someone whose job

involves maximizing our factory's profits. Now this person requires data

- he needs to know how much it costs to operate the ovens - and how

much product we run through them - and how much of that product is

"off-spec" and wasted. The best way to get all of this production data

is to ask the PLC's - after all, they're the "brains" that are

controlling the system. So let's upgrade the old HMI that the operator

has been using - to something with more features. This will be called a

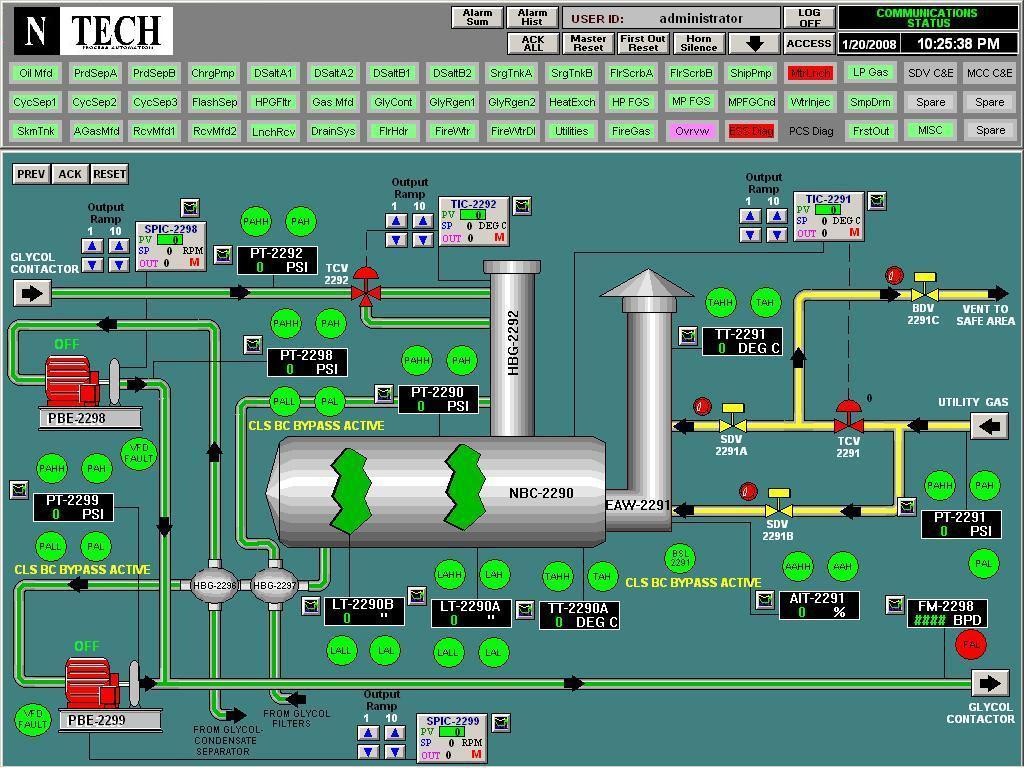

SCADA system - for "Supervisory Control And Data Acquisition". It will

still have control screens with all of the virtual buttons and meters

and other whatnots that the operator needs to control the ovens - but it

will also have some additional features beyond the HMI - features which

will allow the SCADA system to suck the production data right out of

the PLC's - and to store that data in some type of computer database.

Later, the bean-counter can retrieve that production data and analyze it

to his little heart's content. All is well.

Quick review so

far: The machinery in our factory is being controlled by PLC's. For a

little while we used an HMI (Human/Machine Interface) software package -

so that the Human operator could Interface (that is, monitor and

operate) the Machine. Later we moved from the HMI up to a more powerful

software package - a SCADA (Supervisory Control And Data Acquisition)

system. This new software still allowed our human operator to Supervise

and Control the system - and it also added some features for Data

Acquisition for the bean-counter's benefit.

Now let's start over with a new factory - and this time we'll use a DCS (Distributed Control System).

Suppose

that this time we know in advance that the factory we're about to build

is going to involve a rather sophisticated process - one which is going

to require many interrelated steps - all of which must be carefully

coordinated in order to produce a sellable final product. We're talking

about chemicals - or pharmaceuticals - or something along those lines.

(The term "continuous process" is a familiar buzzword for something like

this.)

Now yes, we COULD use PLC's for this type of factory -

and yes, we COULD use a SCADA system to supervise and control the whole

thing. But - many engineers would decide to go with a DCS for something

like this. And that's what we're going to do.

Now suppose that

our new factory still needs something along the lines of our previous

ovens - how would we control these? Instead of putting a PLC on each

oven - we'll use a separate DCS "controller" for each oven. Now at first

glance, these controllers will each look a lot like an individual "I/O

module" or "I/O card" in a PLC system. They usually slide right into a

chassis - and have wires for inputs and outputs connected to the front

of them. So most DCS systems tend to look a lot like a PLC system. The

big difference is that each of these DCS "controller/card" devices will

be individually programmed. That's where the term "DISTRIBUTED" comes

from - the control (or "brain-power" if you prefer) is DISTRIBUTED among

many individual controllers. Specifically, in a typical PLC system we

generally have only one "brain" (or processor) in each chassis - and

then several I/O (input/output) modules in the chassis to handle the

signal wires to-and-from the machinery. On the other hand, in a typical

DCS system we'll have several "brains" (or controllers) in a chassis -

and the I/O wiring associated with each particular "brain's" machinery

will be connected directly to the front of that individual controller.

Now

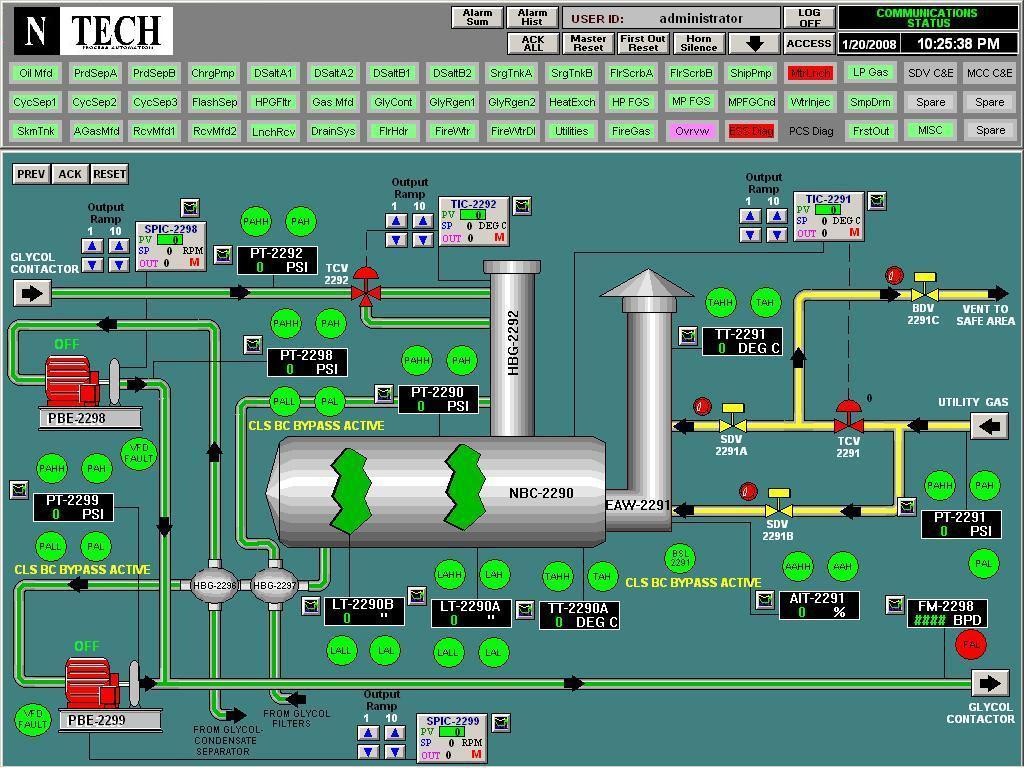

what about the operator control function? Well, one integral part of a

DCS system is a large computer (usually a quite powerful one) which

looks a lot like a SCADA terminal. And it does exactly the same job.

First, it gives the operator a series of control screens with all of the

virtual buttons and meters and other whatnots that he (or she) requires

in order to control the machinery. Second, it also has the features

required to suck the production data right out of the individual

controllers - and to store that data in some type of computer database.

And in most DCS systems, there is a third function of the DCS terminal:

The programming software for the individual controllers is also usually

available on this terminal - so that reprogramming the controllers is

possible right over the existing data communication cables.

Quick

review of the DCS approach: The machinery in our factory is being

controlled by many individual little controllers. Our operator uses a

DCS terminal (computer) to monitor and operate the machinery. This DCS

terminal also has features to acquire production data and store it in a

database for later analysis. Additionally, the DCS terminal usually has

the programming software required for the individual controllers

available. And all of the hardware and all of the software required for

our DCS system is generally provided by just one manufacturer. Some

people think that's a good thing - and other people think that's a bad

thing.

So which is the better approach - PLC or DCS? This is

usually decided by the engineers who initially design the factory. And

in practice, there are a lot of factories out there who use combinations

of the two approaches.

Finally: Please remember that this was

intended to be a general "beginner level" discussion - there are

exceptions to all of these "rules" ... but hopefully this will give you a

"starting point" from which to build.

God bless us all.....:)